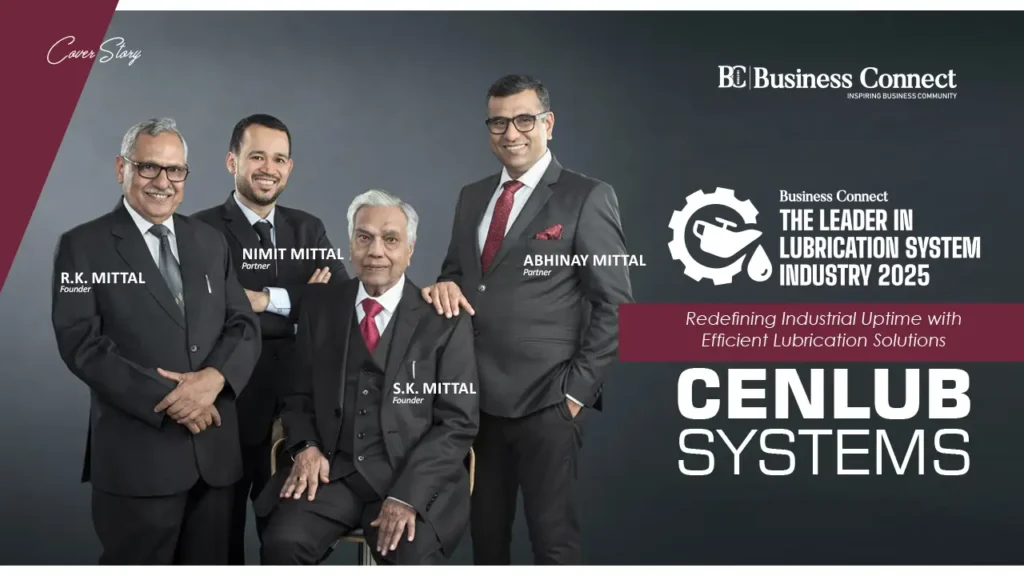

ANSWRS has become the new face of Cenlub Systems, emerging as India’s trusted name in advanced lubrication technology. With over 35 years of expertise, they have successfully transformed industrial lubrication into a science of precision, reliability, and performance. From Machine Tools to Steel, Cement, Power, Sugar, and Material Handling, their solutions drive uptime, reduce wear, and enhance profitability for industries across the globe. Abhinay Mittal and Nimit Mittal are at the helm of the company’s growth. They sat down for a freewheeling conversation with our team to share some lesser-known facts about the company’s extraordinary journey in the industry.

The business portfolio

The company’s new avatar as “ANSWRS” reflects a deeper commitment to being solution-centric, value-driven, and technologically future-ready. It’s not just a name; it represents their belief that every industrial challenge deserves the right answer.

CENLUB SYSTEMS Product Portfolio:

- Single Shot Automatic Lubrication Systems

– Honey / ALU / ELU - Progressive Lubrication System

- Dual Line Lubrication System

- Oil Circulation Systems (OCS)

- Turnkey Lube Projects

- Air Oil Mix System

- Girth Gear Spray System

- Wind Mill Lubrication Systems

- Digital Support: ANSWRS Care

Translating vision into actionable strategies

To translate their vision into action, the team breaks it down into clear, measurable Short Term Goals. These short term goal define objectives for each department, from RFQ to Implementation (sales to service). Regular alignment meetings are conducted to ensure everyone understands not just what is being done, but why it’s being done. Each goal is supported with detailed execution plans, timelines, and accountability. They also believe in empowering teams with the right tools, autonomy, and feedback mechanisms so everyone feels both responsible and inspired to contribute.

With the help of integrated CRM and ERP systems, the organization ensures that accurate, real-time data is available across teams, enabling better decision-making and tracking of progress. Most importantly, they keep the customers’ voice at the center of every strategy, because when real-world problems are solved consistently, the vision naturally comes alive.

Evolution of the Lubrication Industry Industry

Leaders Abhinay Mittal and Nimit Mittal explained that the lubrication industry is evolving with a strong focus on sustainability and cost-efficiency. There’s a shift toward biodegradable, low-toxicity lubricants and advanced systems that reduce waste and optimize dosage. As lubricants become more sophisticated and expensive, dose optimization helps lower customer costs without compromising performance. At ANSWRS, the team strives toward a circular economy by optimizing lubricant consumption through proven dosage/ metering valves. They promote efficient delivery systems and dose optimization that align with both operational and environmental goals.

Balance innovation with practicality

In a value-driven market like India, balancing innovation with practicality means focusing on what truly delivers impact at the ground level.

ANSWRS designs solutions that are not only technologically advanced but also easy to use, reliable, and tailored to real operating conditions — including dusty environments, variable power, and skill gaps. Every innovation brought forth is evaluated against Return on Investment (ROI), ensuring it adds measurable value, not just complexity.

By listening to end users, understanding field challenges, and keeping affordability in mind, the company develops systems that solve real problems, not just to look good on paper. At ANSWRS, customer voice and pain areas serve as the foundation for designing and developing economical, sustainable solutions for both customers and the industry as a whole.

Automated Lubrication Systems

The demand for automated lubrication systems (ALS) is growing rapidly as industrial equipment becomes larger, more complex, and increasingly difficult to maintain manually. With ongoing manpower shortages, industries are turning to automation for consistent and precise lubrication, reducing wear, preventing breakdowns, and lowering maintenance costs. Integration with IoT and real-time monitoring enables predictive maintenance, enhancing uptime and operational efficiency.

These systems also support sustainability efforts by minimizing lubricant waste and facilitating the use of eco-friendly lubricants. From steel and mining to automotive and energy, automated lubrication has become essential for reliable and cost-effective operations. Currently, the adoption of ALS in India stands at only 12 to 14%, compared to global adaptability rates of over 18 to 21%. This presents a significant opportunity for growth across multiple industry segments. As industries move beyond Industry 4.0 and embrace the adoption of AI and ML, the sky is the limit for automated lubrication systems.

The leading edge

The biggest USP of ANSWRS is that it doesn’t just sell lubrication systems — it delivers uptime. What sets ANSWRS apart is its deep application knowledge, customized solutions, and a sharp focus on long-term performance rather than one-time supply, service, or spares. This commitment is reflected in its dedicated support initiative, ANSWRS Care.

With over 15,000 installations and more than 2 lakh lubrication points serviced annually, ANSWRS has rightfully earned the title of “THE OEM CHOICE.” The company boasts an in-house design team and offers a comprehensive product portfolio that includes both oil and grease systems. Backed by robust service support through ANSWRS Care, its systems are engineered for precision, reliability, and efficiency, designs based on real-world feedback from industries such as steel, machine tools, cement, power, and more.

Is technology influencing lubrication equipment design and efficiency?

IoT and smart technologies are transforming lubrication systems from passive components to intelligent assets. Today’s systems can monitor pressure, flow, and temperature in real-time, ensuring precise delivery and early detection of failures.

Smart controllers with remote access and data logging help in predictive maintenance, reducing unplanned downtime and optimizing lubricant usage. At ANSWRS, they’re actively integrating such features to provide customers with data-driven reliability, smarter diagnostics, and better control—ultimately making lubrication systems more efficient, accountable, and aligned with Industry 4.0 goals.

Relying on customer insights

Customer insights are at the heart of everything ANSWRS does. The team stays closely connected with users through direct feedback, service visits, and application audits. Every challenge shared—whether related to performance, service, or integration—serves as a valuable input for continuous improvement.

Product development at ANSWRS is driven by real conversations. The company tracks service data, gathers feedback post-installation, and collaborates closely with OEMs and end users to refine even the smallest features. This user-centric approach has led to the evolution of smarter systems, intuitive designs, and support models like ANSWRS Care that deliver real, lasting value.

Sustainability in manufacturing

At ANSWRS, sustainability is an integral part of how the company designs, manufactures, and delivers its solutions. The team follows lean manufacturing practices to reduce material waste and optimize energy usage. Systems are modular and serviceable, minimizing the need for complete replacements and promoting long-term use.

The company has implemented solar energy at its facilities, reduced plastic and paper usage through digitization, and encouraged the use of biodegradable lubricants wherever applicable. These efforts are backed by recognized certifications like ISO 9001, 14001, 45001, Best Places to Work, and ZED Gold — validating ANSWRS’ commitment to quality, environmental responsibility, and workplace safety. With every innovation, ANSWRS aims to support not just operational efficiency but also a cleaner, more sustainable industrial future.

A culture of innovation and adaptability

At ANSWRS, innovation isn’t confined to a department — it’s a mindset fostered across teams, claimed the duo. The company encourages open dialogue, cross-functional collaboration, and actively involves frontline teams in solution-building, recognizing that they understand real-time challenges best. Regular brainstorming sessions, customer feedback reviews, and internal pitch platforms like ANSWRS Aces provide space for new ideas to emerge. The organization also invests in continuous training, exposure to emerging technologies, and leadership mentoring to keep teams agile. Most importantly, employees are given the space to experiment, fail fast, and learn faster — a culture where adaptability truly thrives.

Pushing the boundaries

ANSWRS remains inspired by staying close to the problem. Every customer challenge, whether it’s downtime, efficiency loss, or service gaps, fuels the team’s drive to find smarter solutions. Motivation also stems from witnessing the real-world impact of their work: smoother-running machines, more efficient plants, and trusted systems. The team remains committed to constant learning through industry trends, customer insights, and collaborative innovation, and never assumes they’ve “arrived.” This ongoing curiosity and the desire to make things simpler, smarter, and more reliable keep ANSWRS pushing forward.

Notches on the belt

Over the years, ANSWRS has achieved several key milestones that reflect their growth and commitment to excellence:

- 1500+ lubrication systems installed every month across major industries including machine tools, steel, cement, sugar, and power.

- More than 20,000 lubrication points are covered every month, demonstrating the scale of our impact.

- Proud recipient of ZED Gold Certification for quality and sustainability.

- Recognized with the India 5000 Best MSME Award, Indian Achievers Award, and Top 10 Lubrication Systems Provider award.

- Recently honored with the Best Places to Work certification, reinforcing our people-first approach.

- Successful development of innovative product lines like Honey Series, Rhyno Pump, WindPro, and our digital-first service model, ANSWRS Care.

- Expansion into international markets and ongoing projects in Europe, South America, and Africa.

Envisioning the next five years

The lubrication industry is heading toward a smarter, more sustainable, and highly integrated future. Over the next 5 to 10 years, ANSWRS envisions IoT-enabled lubrication systems becoming the norm, with real-time monitoring, predictive maintenance, and data-driven decision-making replacing manual checks, stated both the leaders. Sustainability will lead innovation—ecofriendly lubricants, low-waste systems, and energy-efficient designs will become standard expectations.

Customers will no longer just buy a product; they’ll seek complete reliability solutions—faster service, remote support, and intelligent diagnostics. The industry is also expected to become more collaborative, with OEMs, automation players, and digital solution providers coming together to create cohesive ecosystems. ANSWRS is preparing for this shift by building capabilities in smart systems, expanding its global reach, and staying deeply connected with evolving customer needs. The future is about delivering both value and volume, and ANSWRS is fully ready for it.

From the Desk of the Leaders

“Solve real problems, and stay close to the people facing them.

Global impact doesn’t start with scale—it starts with relevance. Listen deeply, build with purpose, and stay consistent. The world doesn’t need more noise; it needs more value. If your solution truly makes someone’s life or work better, the world will open up for you.”