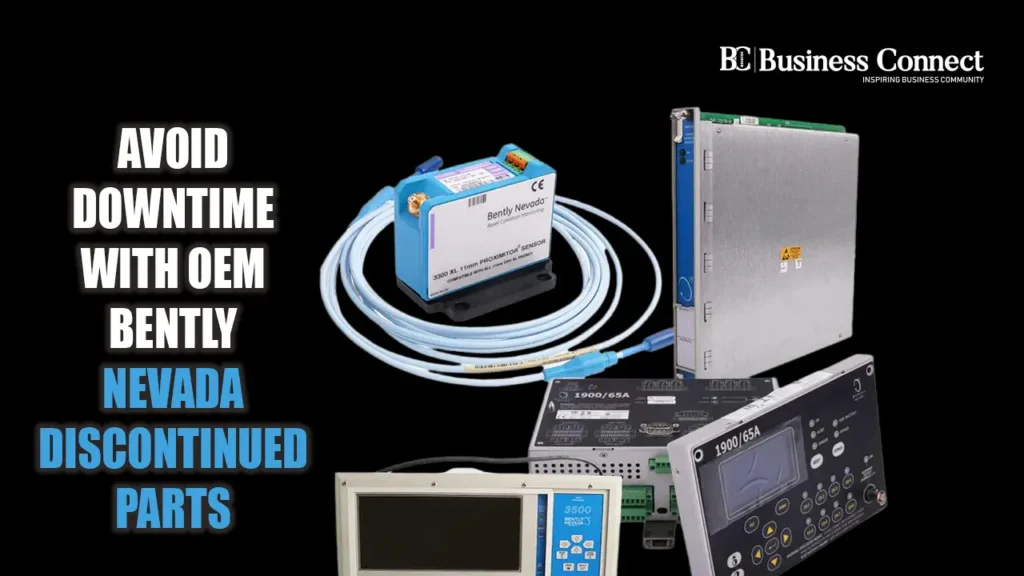

Avoid Downtime with OEM Bently Nevada Discontinued Parts

Industrial facilities worldwide depend on Bently Nevada 3500/20 rack monitoring systems to protect critical rotating machinery and prevent catastrophic failures. These sophisticated systems continuously monitor vibration, temperature, and other vital parameters, providing early warning signals that help maintenance teams avoid costly unplanned shutdowns. However, as equipment ages and technology evolves, many essential components become discontinued by manufacturers, creating significant challenges for operations teams.

When a critical part fails and the original equipment manufacturer no longer produces it, facilities face extended downtime that can cost thousands of dollars per hour. The temptation to use cheaper aftermarket alternatives is strong, but these substitutes often compromise system integrity, void warranties, and introduce compatibility issues that create more problems than they solve.

The solution lies in establishing reliable channels to authentic OEM discontinued parts through specialized suppliers who maintain inventory of obsolete components. By securing access to genuine Bently Nevada parts, even those no longer in active production, facilities can maintain system performance and minimize operational disruptions.

The Importance of OEM Bently Nevada 3500/20 Parts

Original equipment manufacturer parts are engineered to exact specifications that match the design tolerances and performance requirements of Bently Nevada monitoring systems. These components undergo rigorous testing protocols that verify their ability to function accurately under extreme industrial conditions, including high temperatures, vibration exposure, and electromagnetic interference. When facilities install OEM parts, they receive components manufactured with identical materials, circuitry designs, and quality control standards as the original equipment, ensuring seamless integration with existing systems.

Aftermarket alternatives may appear functionally similar and offer immediate cost savings, but they frequently fall short in critical performance areas. Generic replacement parts often use lower-grade materials that degrade faster under operational stress, leading to premature failures and repeat replacements that ultimately cost more than authentic components. The precision calibration required for vibration monitoring cannot be guaranteed with non-OEM parts, potentially causing false alarms that waste maintenance resources or, worse, missed warnings that allow equipment damage to progress undetected.

Beyond performance considerations, using authentic OEM parts preserves manufacturer warranties and support agreements that protect substantial equipment investments. Most Bently Nevada service contracts explicitly require genuine parts for repairs and replacements, with aftermarket substitutions voiding coverage entirely.

This warranty compliance becomes especially valuable when troubleshooting complex system issues, as manufacturer technical support teams can confidently diagnose problems without questioning whether unauthorized components have compromised system behavior. Facilities that maintain OEM standards throughout their monitoring infrastructure gain peace of mind knowing every component meets the manufacturer’s original reliability benchmarks.

Challenges of Finding Discontinued Bently Nevada Parts

Maintenance teams encounter discontinued part situations when aging Bently Nevada systems require component replacements that manufacturers have phased out of production. A proximity probe fails in a power generation turbine monitoring system, or a rack interface module malfunctions in a petrochemical compressor application, only for procurement teams to discover the exact part number has been obsolete for years.

These scenarios force facilities into urgent searches for components that no longer appear in standard distribution channels, creating pressure-filled situations where every hour of delay extends costly production interruptions.

The search for obsolete inventory presents multiple obstacles that complicate rapid resolution. Standard industrial suppliers typically stock only current-production items, leaving maintenance teams to navigate unfamiliar territory of surplus dealers, online marketplaces, and international brokers. Each potential source requires verification efforts to confirm part authenticity, compatibility with specific system configurations, and functional condition after potentially years of storage. Geographic distance adds shipping delays, while language barriers and payment uncertainties introduce additional complications when sourcing from overseas suppliers.

Industrial operations cannot afford the luxury of extended procurement timelines when critical monitoring systems go offline. A failed rack power supply doesn’t just disable one sensor—it can take down an entire monitoring chain protecting millions of dollars in rotating equipment. Production schedules, contractual delivery commitments, and safety regulations all demand rapid restoration of monitoring capabilities. This time sensitivity forces difficult decisions between waiting for verified OEM parts or accepting questionable alternatives that promise faster availability but carry significant performance risks.

Solutions for Sourcing Bently Nevada Discontinued Parts

Working with Authorized OEM Suppliers

Identifying reputable suppliers begins with verification of their authorization status directly through Bently Nevada or Baker Hughes distribution networks. Authorized distributors maintain documented relationships with manufacturers, providing access to verification systems that confirm part authenticity through serial numbers and certification records. Check supplier credentials by requesting authorization certificates, reviewing their history with the manufacturer, and confirming they appear on official distributor lists published by Bently Nevada.

Authorized distributors offer distinct advantages that justify their selection over generic brokers. These suppliers receive factory training on proper handling and storage protocols that preserve component integrity during warehousing periods. They maintain climate-controlled facilities that prevent moisture damage and electrostatic discharge risks that compromise sensitive electronic modules. When questions arise about compatibility with specific rack configurations or firmware versions, authorized suppliers provide technical consultation backed by manufacturer resources rather than guesswork.

Authenticity verification follows systematic procedures that protect against counterfeit components entering critical systems. Genuine OEM parts include manufacturer markings, holographic labels, and traceable serial numbers that authorized suppliers can validate through manufacturer databases. Request certificates of authenticity with each purchase, documenting the part’s origin and chain of custody from factory to end user, creating an audit trail that supports warranty claims and regulatory compliance requirements.

Understanding Warranty Coverage for Discontinued Parts

Warranty terms for discontinued inventory typically mirror those of current-production components when purchased through authorized channels, though coverage periods begin from the original manufacturing date rather than purchase date. A discontinued module manufactured two years ago and sold today may carry a standard three-year warranty with one year remaining, making manufacturing date verification essential before purchase. Authorized suppliers provide documentation showing when components were produced, allowing accurate assessment of remaining coverage periods.

Verifying warranty status requires obtaining specific information before finalizing purchases. Request the exact manufacturing date, original warranty duration, and any extended coverage options available for discontinued items. Contact Bently Nevada support directly with part serial numbers to confirm warranty eligibility and coverage terms, ensuring no disputes arise when filing claims. Some suppliers offer their own warranty extensions that supplement or replace manufacturer coverage for older inventory, providing additional protection for aging components.

Documentation requirements for warranty claims demand meticulous record-keeping from the moment of purchase. Retain all purchase invoices showing authorized supplier transactions, certificates of authenticity proving OEM origin, and installation records documenting proper handling procedures. Photograph serial number labels immediately upon receipt, capturing clear images that remain legible if physical labels degrade during service. Maintain failure reports detailing operational conditions when components malfunction, providing manufacturers with context needed to evaluate warranty claims for parts that may have spent years in storage before installation.

Best Practices for Managing Obsolete Parts Inventory

Proactive parts management begins with comprehensive system audits that identify components approaching end-of-life status before failures occur. Maintenance teams should maintain detailed inventories of all Bently Nevada modules, recording part numbers, installation dates, and manufacturer lifecycle announcements. Monitor Baker Hughes technical bulletins and product discontinuation notices to anticipate when critical components will transition to obsolete status. When manufacturers announce phase-outs, purchase strategic quantities of high-failure items immediately while authorized distributors still carry fresh stock, avoiding premium prices and authenticity concerns that emerge once production ceases.

Contingency planning for critical components requires risk assessment that prioritizes parts based on failure probability and operational impact. Identify single-point-failure components where no redundancy exists—rack power supplies, processor modules, and communication interfaces that would disable entire monitoring chains if they failed. Establish minimum stock levels for these mission-critical items, balancing carrying costs against downtime expenses that dwarf inventory investments. Document alternative part numbers and cross-reference information for components with multiple compatible versions, creating quick-reference guides that accelerate procurement during emergency situations when research time compounds downtime costs.

Building relationships with specialized spare parts services transforms reactive scrambling into strategic partnerships. Establish accounts with multiple authorized distributors who specialize in obsolete industrial automation components, comparing their discontinued Bently Nevada inventories and response capabilities.

Suppliers like Apter Power, which focus on automation and industrial spare parts, often maintain extensive inventories of hard-to-find components that standard distributors no longer stock. Negotiate framework agreements that pre-approve pricing structures and delivery terms, eliminating procurement delays when urgent needs arise. Regular communication with these partners provides advance notice when rare components become available through equipment decommissioning or surplus channels, offering opportunities to acquire backup inventory before other facilities claim limited stock.

Securing Your Facility’s Monitoring System Reliability

Maintaining operational continuity in industrial facilities requires unwavering commitment to system reliability, and authentic OEM Bently Nevada parts form the foundation of that reliability. When critical monitoring components fail, the quality of replacement parts directly determines whether facilities experience brief interruptions or extended shutdowns that cascade into production losses and safety concerns. Genuine discontinued parts preserve the precision engineering and performance standards that make Bently Nevada systems industry benchmarks, while aftermarket shortcuts introduce variables that compromise protection of valuable rotating machinery.

The solutions outlined—establishing relationships with authorized suppliers, implementing proactive inventory management, and understanding warranty protections—transform the challenge of obsolete parts from crisis situations into manageable procurement activities. Facilities that adopt strategic approaches to discontinued component sourcing position themselves ahead of failures rather than reacting to emergencies.

Begin today by auditing current system configurations, identifying vulnerable components approaching obsolescence, and connecting with specialized distributors who maintain authenticated OEM inventory. This proactive planning creates resilience that keeps monitoring systems operational, production lines running, and maintenance budgets predictable, ensuring that discontinued part numbers never translate into discontinued operations.